Leave Your Message

Choosing the right studs boxes is crucial for project success. Professionals agree on the importance of this selection. Studies indicate that improper choices can lead to costly mistakes. For instance, a report by the National Electrical Contractors Association reveals that incorrect stud box installations can increase project costs by up to 20%.

When evaluating studs boxes, consider various factors, including size, material, and functionality. Not all options serve the same purpose. Some may be designed for specific wiring needs, while others might not meet safety standards. Real-world experiences show that overlooking these details can result in significant setbacks.

Data from industry surveys stresses analyzing each project’s requirements before purchasing. A poor choice can compromise not just the installation but the entire electrical system. Examine reviews and seek expert opinions to mitigate risks. Ultimately, being thorough in your selection process can save both time and money in the long run.

When selecting studs boxes, it’s crucial to understand the different types available. Standard studs boxes are most common. They come in various sizes, accommodating different wall thicknesses. Their versatility makes them suitable for many projects.

Then there are old-work studs boxes. These are designed for retrofitting into existing walls. They don’t require extensive modifications, making installation simpler. However, securing them can be challenging. Some users report difficulties with stability after installation.

Finally, there are special-purpose studs boxes, which cater to specific needs. For example, some feature built-in switches or outlets. Others are designed for outdoor use. While these options seem convenient, users might overlook compatibility with their existing systems. Mistakes can be costly. Taking time to analyze each type before deciding is essential.

| Type of Studs Box | Material | Size (inches) | Weight Capacity (lbs) | Ideal Use Case |

|---|---|---|---|---|

| Standard Studs Box | Plastic | 18 x 12 | 50 | General DIY Projects |

| Heavy-Duty Studs Box | Metal | 24 x 16 | 150 | Construction Use |

| Modular Studs Box | Plastic | 20 x 14 | 75 | Organizing Tools |

| Waterproof Studs Box | Plastic | 18 x 12 | 65 | Outdoor Applications |

| Stackable Studs Box | Plastic | 22 x 14 | 80 | Space-saving Storage |

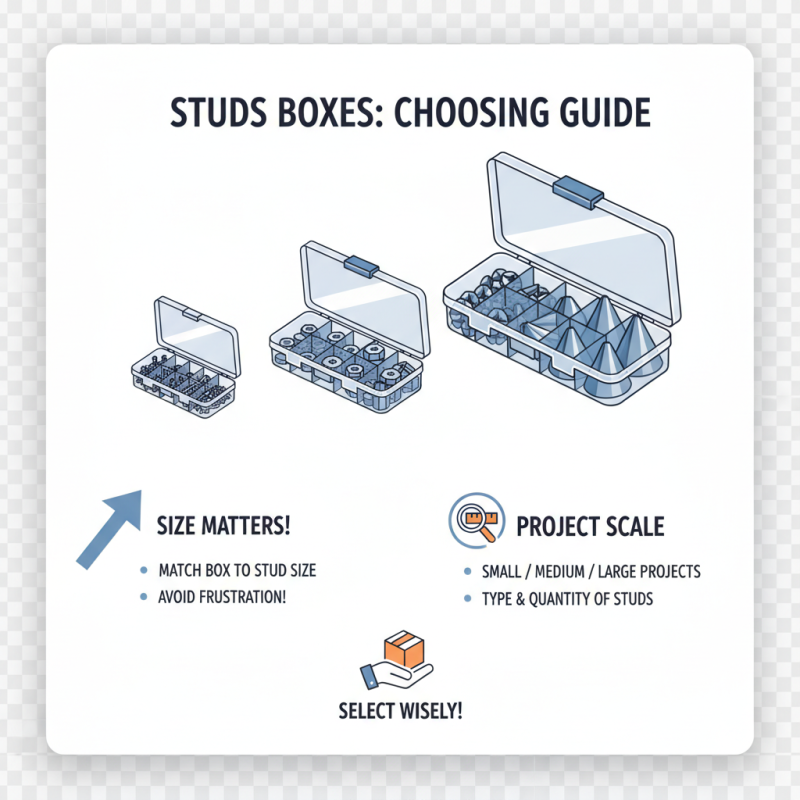

When choosing studs boxes for your projects, several key factors come into play. Consider the size of the studs you plan to use. Different boxes accommodate various sizes. Make sure the box size matches your needs. It's frustrating to purchase a box only to find it too small.

Next, evaluate the material of the studs box. Plastic and metal options exist, each with its own pros and cons. Plastic is lightweight but may not offer the best durability. Metal provides sturdiness but can be heavier and more expensive. Think about the environment where you will use the box. A DIYer may prefer something that withstands rough handling.

Don’t forget to consider organization features. Some boxes come with dividers, while others do not. If you have many types of studs, dividers can help keep them sorted. However, a box without them may seem spacious but could lead to a chaotic mess. Reflect on your working style. Will you need to quickly access specific types? Organization might tip the scales in favor of a more compartmentalized box.

When selecting studs boxes for your projects, material quality and durability are critical. Many options are available, from plastic to metal. Plastic is often lighter and easier to handle. However, it may not withstand heavy-duty use as well as metal options. Think about what you'll be doing. If it’s for a long-term project, durability becomes vital.

Consider how the boxes will be used. Will they face harsh weather, or will they be stored indoors? Metal studs boxes usually offer better protection against corrosion and wear. But, they can be heavier and pricier. So, evaluate your budget. A more expensive, durable option might save you money over time.

Don’t overlook reviews or personal experiences with various materials. Some users report plastic boxes cracking unexpectedly. Others mention metal boxes may dent under pressure. These real-world insights can help you make a more informed choice. Balancing quality and cost requires reflection on your project's specific needs. Make a thoughtful decision, and remember—what works for one project may not work for another.

When selecting studs boxes for your projects, budgeting is crucial. Costs can vary significantly based on materials and sizes. A simple box may cost less, but if it lacks durability, you could face issues later. It's essential to analyze what your project truly needs. A lower cost upfront could lead to higher expenses in the long run.

Consider the total expenses involved. Sometimes, it's wise to invest a bit more for quality. A more robust studs box can prevent losses tied to frequent replacements. Think about how often you'll use the box and for what purposes. If it's for a one-off project, sticking to a strict budget may work. On the other hand, if it's for ongoing tasks, don’t be afraid to splurge a little. It’s okay to rethink your initial budget if the quality justifies it.

You may realize that cutting corners isn’t always the best approach. The initial savings can quickly disappear with repairs. Assess your needs carefully. Try to balance adequate features with your financial plan. Reflect on prior projects. What did you overlook? What can you improve? This reflection can guide you to make more informed choices.

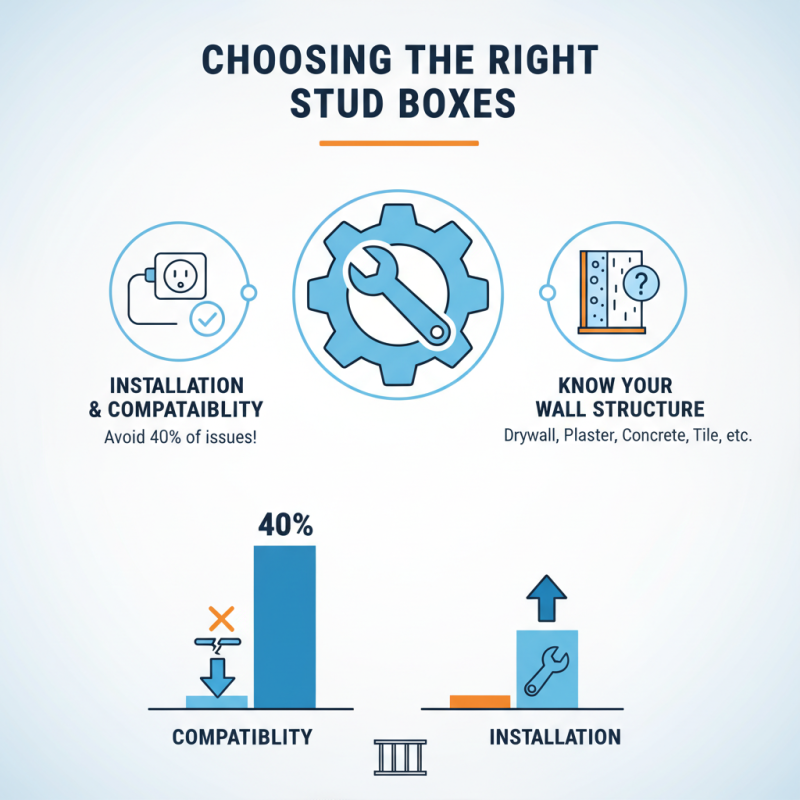

Choosing the right studs boxes can significantly impact your project. Installation and compatibility should always be a priority. Industry reports indicate that nearly 40% of installation issues are due to compatibility oversights. Knowing your wall structure is crucial. For example, drywall, plaster, or any other material may require different designs.

When determining compatibility, consider electronic components, such as switches and outlets. Not every box accommodates every device. For instance, a standard box might not fit specialized switches. Understanding size and depth is vital. A box too deep can complicate fixture installation.

Tip: Always check the electrical ratings before purchase. Ensure they match the demands of your project. This can save future headaches.

Another aspect to reflect on is the volume of cables and wiring inside the box. Overcrowding can lead to serious safety hazards. The National Electrical Code suggests a specific volume reserved for wiring. When estimating, be mindful of cable types and quantities.

Tip: Document your plans before you start. Having a visual reference can clarify what you need. Errors can result in costly delays.